Xinran Nitrogen Generator

PSA nitrogen generator’s basic principle is to make use of sorbent which has different absorption capacity to adsorptive materials under different pressures, and to a certain pressure on the separation of the various components of gas mixtures have the choice of absorption properties.

Characteristics of Nitrogen Generator:

1. The unique molecular sieve pinched protection measures with long using life.

2. Low energy consumption, high-purity nitrogen products

3. Reasonable internal components, evenly distributed air, reducing high-speed airflow impact

4. High degree automation of full set of equipment

5. Multi-function monitoring system, and gas, purity, pressure-line LCD display, equipment failure alarm, maintenance tips, complete control of the equipment operation.

6. Integrated design makes installment and adjustment rapid and simple.

7. Optional nitrogen flow, remote monitoring system, etc.

Specifications of Nitrogen Generator:

Nitrogen Production: 5-2000Nm3 /h

Nitrogen Purity: 95 % -99.995 %

Pressure of Nitrogen Outlet Port: 0.1-0.8MPa

Nitrogen Outlet Dew Point: ≤ -45 ℃

Working Principle of Nitrogen Generator:

SCM Series Nitrogen Generator is based on principles of PSA, which adopts high-quality carbon molecular sieve as adsorbent, to a certain pressure, and forms the production of nitrogen in the air. Compressed air after purifying and drying is pressurized adsorption and decompressed desorption in the absorber. Due to the dynamic effects of air, oxygen’s proliferation rate in carbon molecular sieves micro-pore is far greater than in nitrogen, oxygen is absorbed by carbon molecular sieve priority; thus, nitrogen is enriched and nitrogen products is formed. Then it was decompressed to atmospheric pressure, and becomes adsorbent by adsorption-desorption of oxygen and other impurities.

1. Compressed air is equipped with air drying and purifying processing equipment. Clean dry air is conducive to the long-term life of modular sieve.

2. Reasonable structural design, special air dispersion devices, avoid the impact of high-speed airflow and cause the phenomenon of modular sieve powder.

3. Adopt new type pneumatic valve with fast starting up , long using life and can meet long-term continuous use.

4. The scientific process design, the greatest improvement of the absorption functions of the molecular sieve

5. Compact equipment, small land covering area, air purification components, PSA nitrogen generating system can be installed at the same base, composed of integrated structure

6. Using PLC technological control, and adjusted in accordance with the purity of nitrogen, and can interface with computers for the remote control

7. The use of national patented technology of inside balanced automatically pinched system and the unique molecular sieve filling technology to raise whole machine’s reliability of long-term operation.

Specification Parameter of PSA Nitrogen Generator:

Compressed Air Source: a general compressor offers compressed air for PSA nitrogen generator.

Compressed Air Purifying Components: water, oil and dust in compressed air are processed strictly by high effective oil removal device, dryer and precise filter, which provides clean air for PSA nitrogen generator.

PSA Components: Is made up with two adsorptive towers which are filled with carbon modular sieve as main sorbent.

Nitrogen Buffered Tank: Nitrogen output from adsorptive tower is stabilized by this tank and then outputs for use.

Nitrogen Purification Device: When a user needs O2 ≤ 5 ppm of nitrogen, the nitrogen purification device deoxidizes (JHa type, JHb type), to meet the using requirement.

Good Reliability: It adopts molecular sieve of the best performance at home and abroad, carbon pneumatic valves, and advanced microcomputer. In light of the company’s rich experience in manufacturing, the long-term stable operation of equipment and minimal maintenance are achieved.

Excellent Service: Users can be satisfied and gain good benefits from the equipment, operator training, spare parts supply, after-sales maintenance services, and other aspects of the Company.

Small Air Consumption: Using unique molecular sieve filling technology and perfect design, make molecular sieve not only has long using life, but also can maximize the performance, which can significantly reduce air consumption.

Small Land Covering Area: Assembly design with small land covering area, installation and maintenance are very convenient.

Application Scope of Xinran Nitrogen Generator:

1. Chemical Industry: coverage, replacement, cleaning, purging, delivery of pressure, the protection of chemical fiber production.

2. Heat Process: controlled protection, powder metallurgy and magnetic materials sintering.

3. Beer: Filter, transmission, Sake, the back-pressure, filling.

4. Food Industry: nitrogen filling package, store and keep fresh.

5. Medicine: coverage, nitrogen filling storage, pneumatic transmission

6. Oil and Natural Gas: containers, pipe purging, leakage detection, nitrogen filling and oil injection.

7. Electrical (Optical) Cables: cross-linked (optical) cables to protect gas production

8. Electronics: nitrogen protection of semiconductor and electrical components production.

9. Coal: Underground explosion-proof, coalfield fire proof and fire-fighting.

10. Transportation & Storage: package of goods, transmission of materials pressure, warehousing, insecticidal and anti-fire.

11. Others: rubber industry, aerospace industry, metallurgical industry, offshore oil field exploration, etc.

Pressure Swing Adsorption (PSA) Nitrogen Generator

Pressure Swing Adsorption (PSA) Nitrogen Generator

Technical Parameter of PSA Nitrogen Generator

Advantages of PSA Nitrogen Generator:

◆ Low operation costs; save more money than bottled nitrogen and liquid nitrogen.

◆ Get nitrogen from the air directly.

◆ Small land covering area, easy to operate

◆ Easy installation, safe operation and reliable.

Applications of PSA Nitrogen Generator:

◆ Nitrogen source for large-scale integrated circuits, electronic components and semiconductor processing.

◆ Continuous casting, rolling, steel annealing protection.

◆ Gas protection in welding and powder metallurgy sintering process.

◆ Nitrogen filling package of food and keep fresh.

◆ Pneumatic transmission of plastic particles, plastic production and storage of anti-oxidation

◆ Nitrogen filling purification of tanks, containers, catalytic towers and pipelines.

◆ Package and storage of rubber, tyre production, etc.

◆ Polymerization for paintings and coatings of nitrogen filling and oxygen removing to prevent the oil dry.

◆ Nitrogen filling of western medicine injection, storage tanks and containers, gas source for drug material pneumatic transmission, etc.

Cost Saving and Convenience :

Pressure swing adsorption (PSA) nitrogen generator could avoid inconvenience brought by high cost of bottle nitrogen and DU pottery pots. Meanwhile, the supply of nitrogen does not have to rely on retailers, thus avoiding the danger of the high pressure bottle nitrogen gas and loss of production brought caused by gas supply disruptions. Long-term stability and low-cost operation of PSA nitrogen can avoid uncontrolled increase in the price of gas, and high cost of cryogenic tanks leasing, and can get cost recovery in a short time, therefore, once a nitrogen generator is installed, we can extract nitrogen from the air freely.

Easy Operation and Maintenance of PSA Nitrogen Generator:

◆ Nitrogen production equipment is designed for 24-hour uninterrupted operation.

◆ Equipment operation is under unmanned monitor.

◆ Only the filter element of air compressed system is need to be replaced, nitrogen generator does not need any maintenance.

With the sound and light alarm oxygen analysis instrument (or Nitrogen Analysis Instrument) on-line monitoring nitrogen purity of the system.

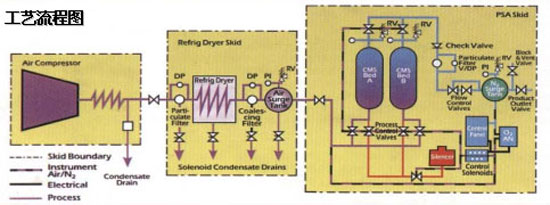

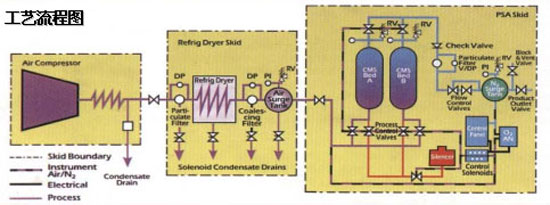

Basic Process of PSA Nitrogen Generator:

PSA Components: nitrogen generator which adopts the most advanced pressure swing adsorption technology is two absorption towers (with GB150-98 standard pressure vessel) made of the following components, which is filled with carbon molecular sieve (CMS) with a start / closed for process control counter to control equipment running through the automatic control valve to maintain the purity and stability. The automatic alarm on-line monitoring oxygen analysis instrument is a standard air compressor component: This is necessary to be included, regardless of the oil or oilless air compressor. Unless the factory has had a reliable source of compressed air for the PSA system.

Purifying System Components: Its function is to provide PSA air processing, this component is made up with a gas storage tank, refrigerant dryer, and filters, to ensure that the PSA absorption tower inhaled is clean compressed air, which prolongs using life of molecular sieve (CMS), to ensure long-term stable and reliable operation of nitrogen production equipment. Oil, water, and dust separated by refrigerant dryer, filter is isolated from the compressed air system automatically.

Technical Index:

Technical Index:

Technical indicators which PSA nitrogen generator can achieve when it extracts nitrogen.

Nitrogen Flowing Capacity:

Nitrogen Purity: 98%—99.9995%

Pressure of Outlet Port: Under 0.8Mpa (adjustable)

Dew Point: -45℃

Working Principle of PSA Nitrogen Generator:

Nitrogen Generator is based on the technology of pressure swing adsorption (PSA), using high-quality carbon molecular sieve as adsorbent, directly separating the oxygen from the compressed air and getting nitrogen. Compressed air after purifying and drying, under pressure, makes use of the proliferation and absorption rate of oxygen in the carbon molecular sieve porous is far greater than nitrogen, the nitrogen gas has been enriched before the adsorption is balanced, and form nitrogen products. Then decompressed to normal pressure, adsorbent by adsorption-desorption of oxygen and other impurities composite, and renewable. Two absorption towers are set up in the system, one tower absorbs nitrogen, and another tower disrobes renewable, controlled by PLC program controller.