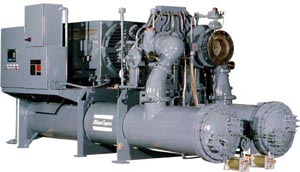

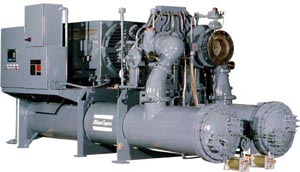

Atlas Copco Centrifugal Air Compressor

H Series Centrifugal Air Compressor

Centrifugal Type – multi-grade

Capacity:1400 to 11,800 L/S,3000 to 25,000 cfm

Specification of Motor:Max. 4500 KW,6000 Hp

Pressure:Max. 27.5 bar,400 psi

High efficiency and economic H series air compressor is widely used in automobile, chemical industry, pharmacy, mining, air separating, etc. Every part of H series air compressor can offer reliable performance.

1- Speed increasing gear with single helical gear: the gear is designed and manufactured by Atlas•Copco, meets the specification of AGMA Q-13 (DIN 5/6).

2- H series impeller: having excellent adjustability.

3- Inlet flow control guide vane: this is an optional accessory which can decrease load and improve performance, and it also can reduce energy consumption by 9%.

4- Interstage pipe: connected by sealing “Victaulic”interface.

5- Horizonally split gearbox: simplify inspection and maintenance of sealing parts and bearing.

6- Optional parallel flowing distributing pipe.

7- Motor which can use various voltage and machine casing.

8- Atlas•Copco PLC controller: monitor key parameter and provide standard data and also can monitor other control system to meet your requirement.

9- Precise and balanced coupling: reduce vibration to minimum, and no lubricant of connector is needed.

10- Complete set of basing: integrate frame, middle cooler and lubricant box.

11- Interstage cooler

GT Centrifugal Air Compressor

33,000 to 10, 0000 m3/h - 20,000 to 60,000 cfm

max. Motor power 8500 KW - 11,500 Hp

max. pressure 13 bar - 188 psi (pressure of meter)

Heavy GT series air compressor is used for air separating industry with large flow of 20,000 to 60,000 cfm(33,000 to 100,000 m3/h)and max. exhaust pressure of 188 psi (13 bar)

1.Best design of impeller increases efficiency

2.Adjustable inlet guide vane (IGV) widens control range

3.Floating carbon ring seal reduces leakage of sealing gas, meanwhile, it can be operated without contact, which is safe and reliable

4.Dry and stacked-disc type coupling, easy to install.

5.There is axial thrust bearing on high speed pinion shaft.

6.Compact and general-used built-in casing cooler has excellent torsional rigidity.

7.Standard control room and various optional accessories.

8.Electrical supporting frame for installing built-in air cooler (GT063) on concrete base or segregated steel base (GT078/GT087).

ZH4000-10000 Oilless Centrifugal Air Compressor

ZH-3:

400-1120 KW - 7.0-10.4 bar(e) - 100-150 psi(pressure of meter)- 4400-11000 m

3/h - 2550-6500 cfm

ZH-2(low pressure):

315-800 KW - 3.5-4.6 bar(e) - 50-65 psi(pressure of meter)- 4400-11000 m3/h - 2550-6500 cfm

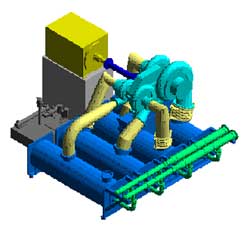

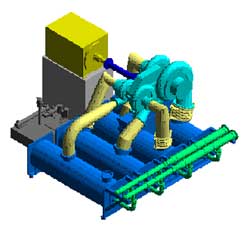

ZH4000-ZH10000 Centrifugal Air Compressor

ZH4000-ZH10000 is the most advanced centrifugal compressor series within low pressure range at present. It can meet customer’s requirements of low installation, running and maintenance cost, high reliability and easy operation.

| Performance |

Advantages |

| Imported filter and silencer |

Two or three-grade type |

| Inlet flow control guide vane |

Low cost, no additional cost |

| After cooler |

Complete plug and play air compressed system |

| Non-return valve and flexible outlet expansion joint |

Simple and economic installation, no basis needed |

| Cooling water manifold |

Low energy consumption |

| Steam trap |

High reliability |

| Expansion joint which is on inlet and outlet port of air and water |

Low-cost and easy maintenance |

| Main motor |

Environment protection |

| Complete lubricating system |

Completely oilless, no sealing air loss |

| Control and security system |

Silence type (option) |

| Built-in adjusting atmospheric valve |