PENUDRI No Heat Regeneration Desiccant Dryer

Characteristics of No Heat Regeneration Desiccant Dryer:

Decrease energy consumption:

DDS dew point energy saving system controls the whole cycling process by continuously monitoring the running load of dryer to decrease energy consumption by 80%.

Protect compressed air system:

remove water vapor in compressed air to prevent the system corroding..

Provide clean and dry compressed air:

equipped with Domnick Hunter OIL-X filter, PENUDRI dryer can offer compressed air of -40℃ dew point.

Reliable performance:

high quality cylinder switching valve ensures reliable switch, and high quality sorbent ensures stable dew point temperature.

Saving space:

Saving space:

advanced aluminum forming technology makes PENUDRI dryer only half of traditional double-tower dryer on both volume and weight, with smaller land covering and easier installation.

Modular design:

unique modular structure of Domnick Hunter avoids complicated valve and pipe connection of traditional double-tower dryer.

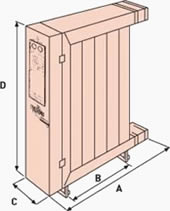

Technical Parameter and Model of No Heat Regeneration Desiccant Dryer:

| Model |

Flow @7barg,35℃ |

Dimensions mm |

Connection Size |

Weight

kg |

| PDP:-20℃ |

PDP:-40℃ |

PDP:-70℃ |

| m3/min |

m3/min |

m3/min |

A |

B |

C |

D |

| MX(*)102c |

7.48 |

6.80 |

4.76 |

696 |

326 |

550 |

1647 |

2" |

235 |

| MX(*)103c |

11.22 |

10.20 |

7.14 |

865 |

495 |

550 |

1647 |

2" |

316 |

| MX(*)103 |

14.03 |

12.75 |

8.93 |

865 |

495 |

550 |

1892 |

2" |

355 |

| MX(*)104 |

18.70 |

17.00 |

11.90 |

1034 |

664 |

550 |

1892 |

2" |

450 |

| MX(*)105 |

23.38 |

21.25 |

14.88 |

1203 |

833 |

550 |

1892 |

2½" |

543 |

| MX(*)106 |

28.05 |

25.50 |

17.85 |

1372 |

1002 |

550 |

1892 |

2½" |

637 |

| MX(*)107 |

32.73 |

29.75 |

20.83 |

1541 |

1171 |

550 |

1892 |

2½" |

731 |

| MX(*)108 |

37.40 |

34.00 |

23.80 |

1710 |

1340 |

550 |

1892 |

2½" |

825 |

| MX(*)109 |

N/A |

N/A |

26.77 |

1879 |

1509 |

550 |

1892 |

3 |

919 |

| MX(*)110 |

N/A |

N/A |

29.73 |

2048 |

1678 |

550 |

1892 |

3 |

1013 |

| MPX(*)110 |

43.01 |

39.10 |

27.37 |

2233 |

1470 |

550 |

1788 |

4" |

895 |

| MPX(*)112 |

51.61 |

46.92 |

32.84 |

2551 |

1798 |

550 |

1788 |

4" |

1025 |

*Control method of dryer:

"S"—Smart Control, DDS dew point energy saving system can be added additionally.

"E"—Electronic Control, DDS dew point energy saving system can be added additionally. |

| Max. working pressure |

13barg |

| Minimum working pressure |

4barg |

| Max. air inlet temperature |

50°C |

| Minimum air inlet temperature |

2°C |

| Sound level |

<75dB(A) |

| Voltage |

415V/3ph+

Neutral/50-60Hz |

1. Choose correction coefficient of minimum inlet pressure of dryer (CFP).

2. Choose correction system of maximum inlet temperature (CFT).

3. Calculation of dryer flowing capacity (air inlet flow) / (CFP×CFT)=minimum flowing capacity of dryer

| Max. inlet temperature(℃) |

25 |

35 |

40 |

45 |

50 |

| Correction factor of temperature(CFT) |

1.1 |

1.0 |

0.76 |

0.58 |

0.45 |

| Max. inlet pressure(barg) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

| Correction factor of pressure(CFP) |

0.63 |

0.75 |

0.88 |

1.0 |

1.13 |

1.25 |

1.38 |

1.5 |

1.63 |

1.75 |

Characteristics of PENUDRI Heat Regeneration Desiccant Dryer:

Decrease energy consumption

DDS dew point energy saving system controls the whole cycling process by continuously monitoring the running load of dryer to decrease energy consumption by 80%.

Protect compressed air system:

remove water vapor in compressed air to prevent the system corroding

Provide clean and dry compressed air:

equipped with Domnick Hunter OIL-X filter, PENUDRI dryer can offer compressed air of -40℃ dew point.

Reliable performance:

high quality cylinder switching valve ensures reliable switch, and high quality sorbent ensures stable dew point temperature.

Saving space:

Saving space:

advanced aluminum forming technology makes PENUDRI dryer only half of traditional double-tower dryer on both volume and weight, with smaller land covering and easier installation.

Modular design:

unique modular structure of Domnick Hunter avoids complicated valve and pipe connection of traditional double-tower dryer.

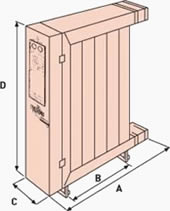

Technical Parameter and Model:

| Model |

Flow @7barg,35℃ |

Dimensions mm |

Interface size |

Weight

kg |

Average Energy Consumption

KWH |

| PDP:-40℃ |

PDP:-70℃ |

| m3/min |

m3/min |

A |

B |

C |

D |

| DH(*)102 |

3.96 |

2.77 |

717 |

264 |

321 |

1578 |

2" |

150 |

1.1 |

| DH(*)104 |

7.92 |

5.54 |

947 |

494 |

321 |

1578 |

2" |

245 |

2.2 |

| DH(*)106 |

11.89 |

8.32 |

1177 |

724 |

321 |

1578 |

2½" |

325 |

3.3 |

| DH(*)108 |

15.85 |

11.10 |

1407 |

954 |

321 |

1578 |

2½" |

440 |

4.4 |

| DH(*)110 |

19.81 |

13.87 |

1637 |

1184 |

321 |

1578 |

2½" |

565 |

5.5 |

*Control Method of Dryer

"S"—Smart Control, DDS dew point energy saving system can be added additionally.

"E"—Electronic Control, DDS dew point energy saving system can be added additionally. |

| Max. working pressure |

13barg |

| Minimum working pressure |

4barg |

| Max. inlet temperature |

50°C |

| Minimum inlet temperature |

2°C |

| Sound level |

<75dB(A) |

| Voltage |

415V/3ph+

Neutral/50-60Hz |

1. Choose correction coefficient of minimum inlet pressure of dryer (CFP)

2. Choose correction system of maximum inlet temperature (CFT)

3. 4. Calculation of dryer flowing capacity (air inlet flow) / (CFP×CFT)=minimum flowing capacity of dryer

| Max. inlet temperature(℃) |

25 |

35 |

40 |

45 |

50 |

| Correction factor of temperature(CFT) |

1.1 |

1.0 |

0.76 |

0.58 |

0.45 |

| Max. inlet pressure(barg) |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

| Correction factor of pressure(CFP) |

0.63 |

0.75 |

0.88 |

1.0 |

1.13 |

1.25 |

1.38 |

1.5 |

1.63 |

1.75 |